4 Input channels

DTC has successfully attended the Automotive Testing Expo China 2023 2023-08-20

Vibro-Shock Test 2022-09-21

How to connect multi-vibration controller? 1970-01-01

VENZO 640 shock test system is the tailored instrument for drop tester, shock tester and bump testing machine. It allows the test engineer to acquire any transient event such as drop test, crash test or shock pulses. When the external input match the defined trigger conditions- trigger level, slope and position, VENZO 640 will trigger to capture the transient event and display the pulse graphics, and additional SRS analysis gives the instant estimation of the potential damage. A series of pulses can be captured and in the mean while throughput to disc in a continuous data stream for post-analysis. VENZO 640 can also control the shock machines’ movements as specific requirements of customers.

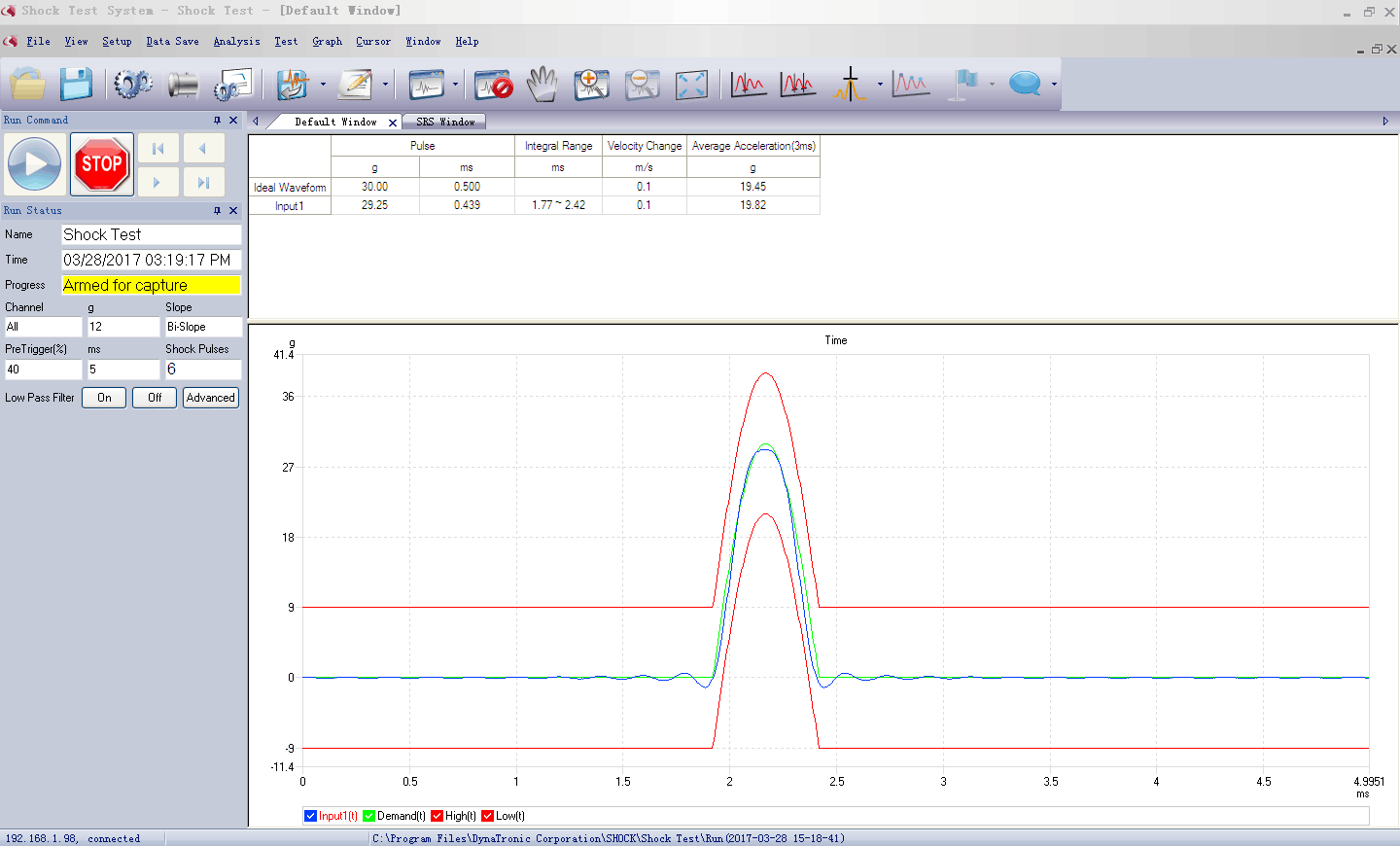

Collect and analyze the test data of shock systems (such as shock machine, bump machine, etc.) that can generate waveforms such as half sine, final peak saw tooth and trapezoidal.

Trigger

Trigger Channel: Any active channel, specified channel or none

Trigger Slope: Rising, Falling and Bi-slope

Trigger Level: Specified level, Percentage of target pulse peak or Specified acceleration level

Pre-trigger: Advance trigger, 0-100%

Ideal Waveform

Waveform: Half-sine, Final peak saw tooth, Trapezoid

Standard: MIL-STD-810G, MIL-STD-202-213, IEC 68-2-27, User defined

SRS Analysis

SRS type: Primary, Residual, and Composite

Resolution: 1-1/48 octave analysis

Reference Frequency: User-defined

Damping Ratio: 0.1%-100%

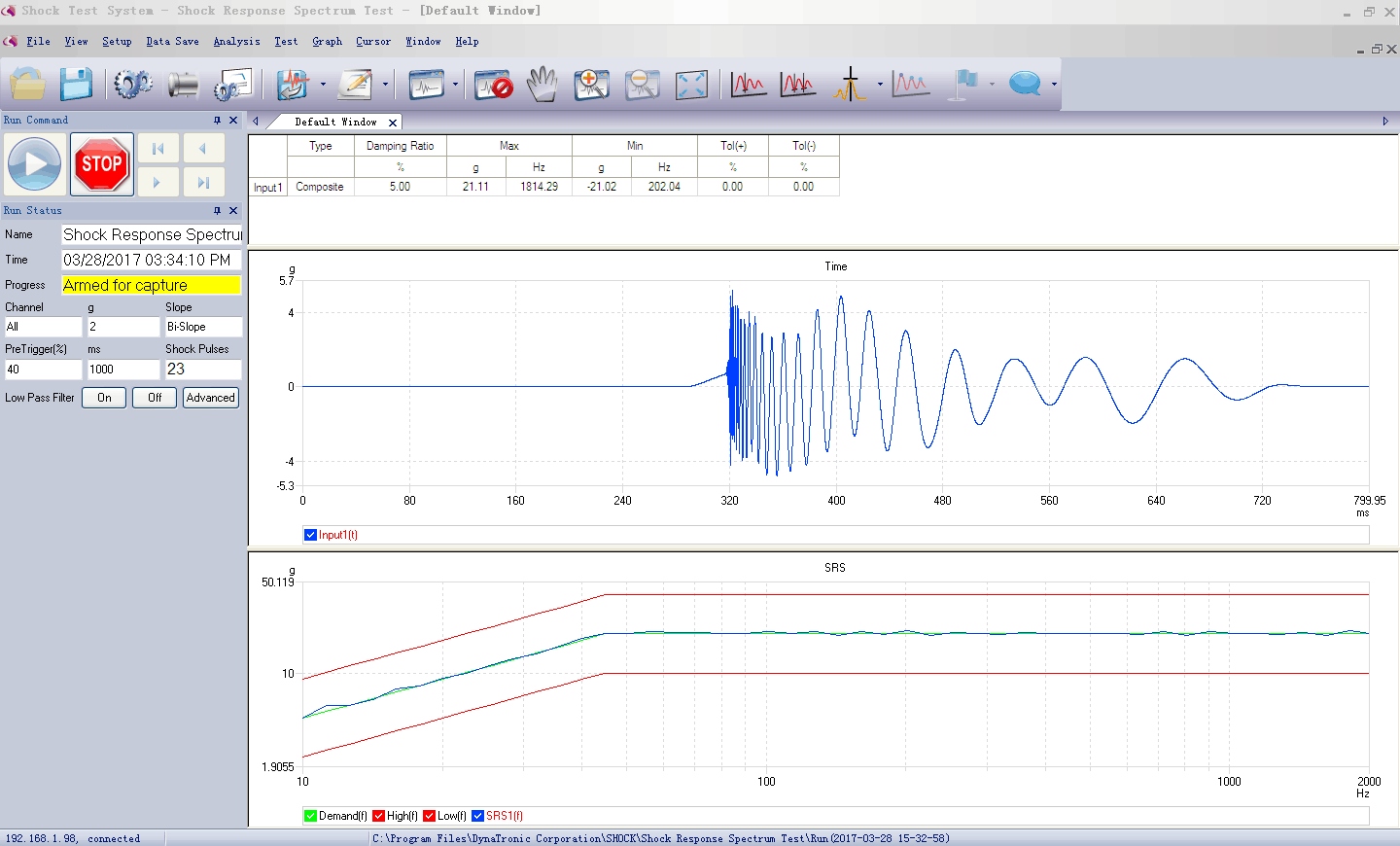

Used to collect and analyze the test data of the shock systems (such as shock response spectrum testing machine) that can generate the corresponding pulse signal.

Reference Spectrum

Setting: Set Frequency, Left / Right Slope, Acceleration Amplitude, Tolerance and other parameters, can calculate break points

Fractional Octave Number (1/N): 1~48

Reference Frequency: User-defined

Trigger

Trigger Channel: Any active channel, specified channel or none

Trigger Slope: Rising, Falling and Bi-slope

Trigger Level: Specified acceleration level

Pre-trigger: Advance trigger, 0-100%

Sampling

Capture Duration: From 1 to 10,000 ms

Sampling Frequency: 320 Hz to 204.8 kHz

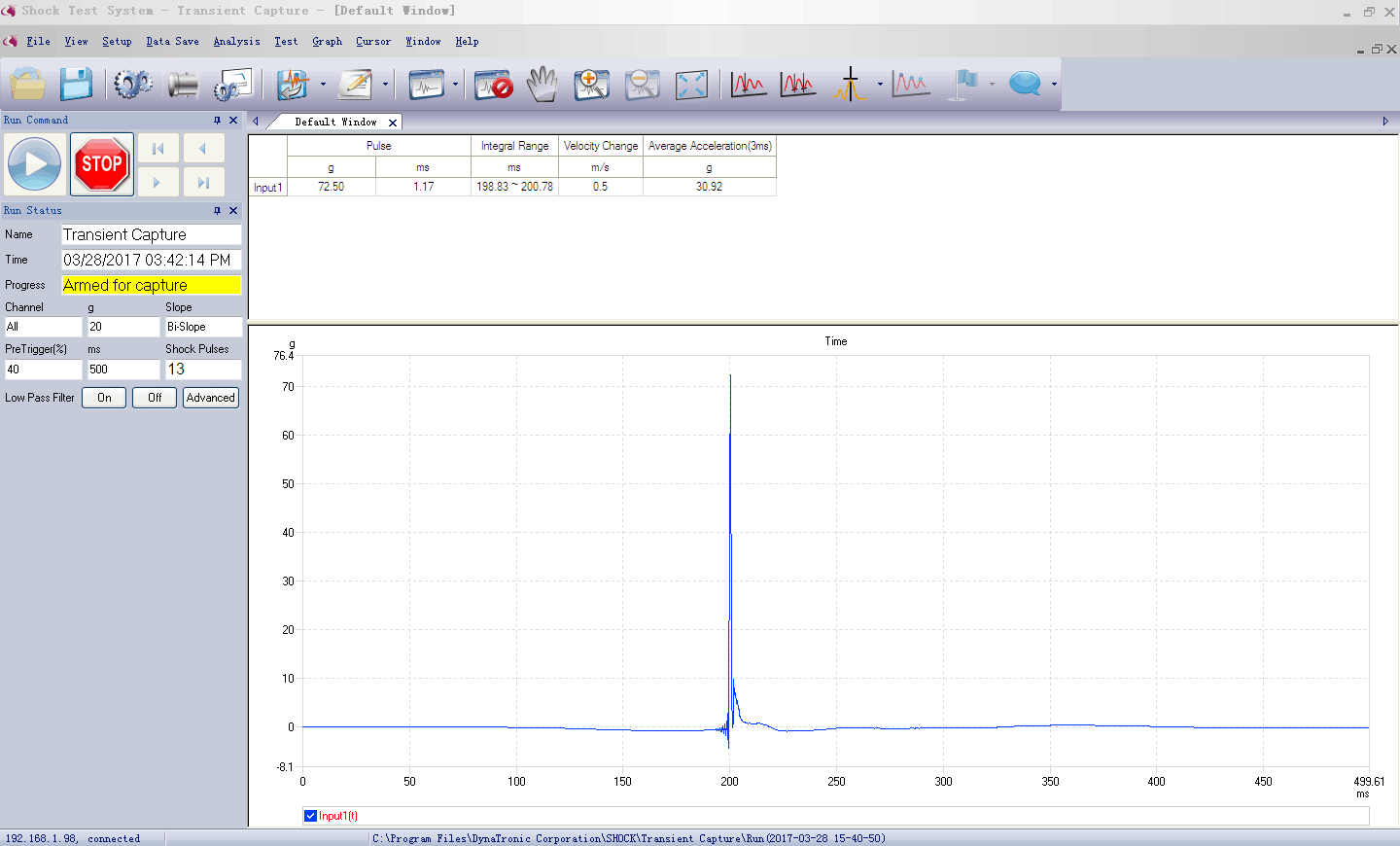

Used to collect and analyze random pulse waveforms, such as explosion shock, etc.

Trigger

Trigger Channel: Any active channel, specified channel or none

Trigger Slope: Rising, Falling and Bi-slope

Trigger Level: Specified level, Percentage of pulse peak, Specified acceleration level

Pre-trigger: Advance trigger, 0-100%

Sampling

Capture Duration: From 1 to 10,000 ms

Sampling Frequency: 320 Hz to 204.8 kHz

SRS

SRS Type: Primary, Residual and Composite

Fractional Octave Number (1/N): 1~48

Reference Frequency: User-defined

Damping Ratio: 0.1%~100%

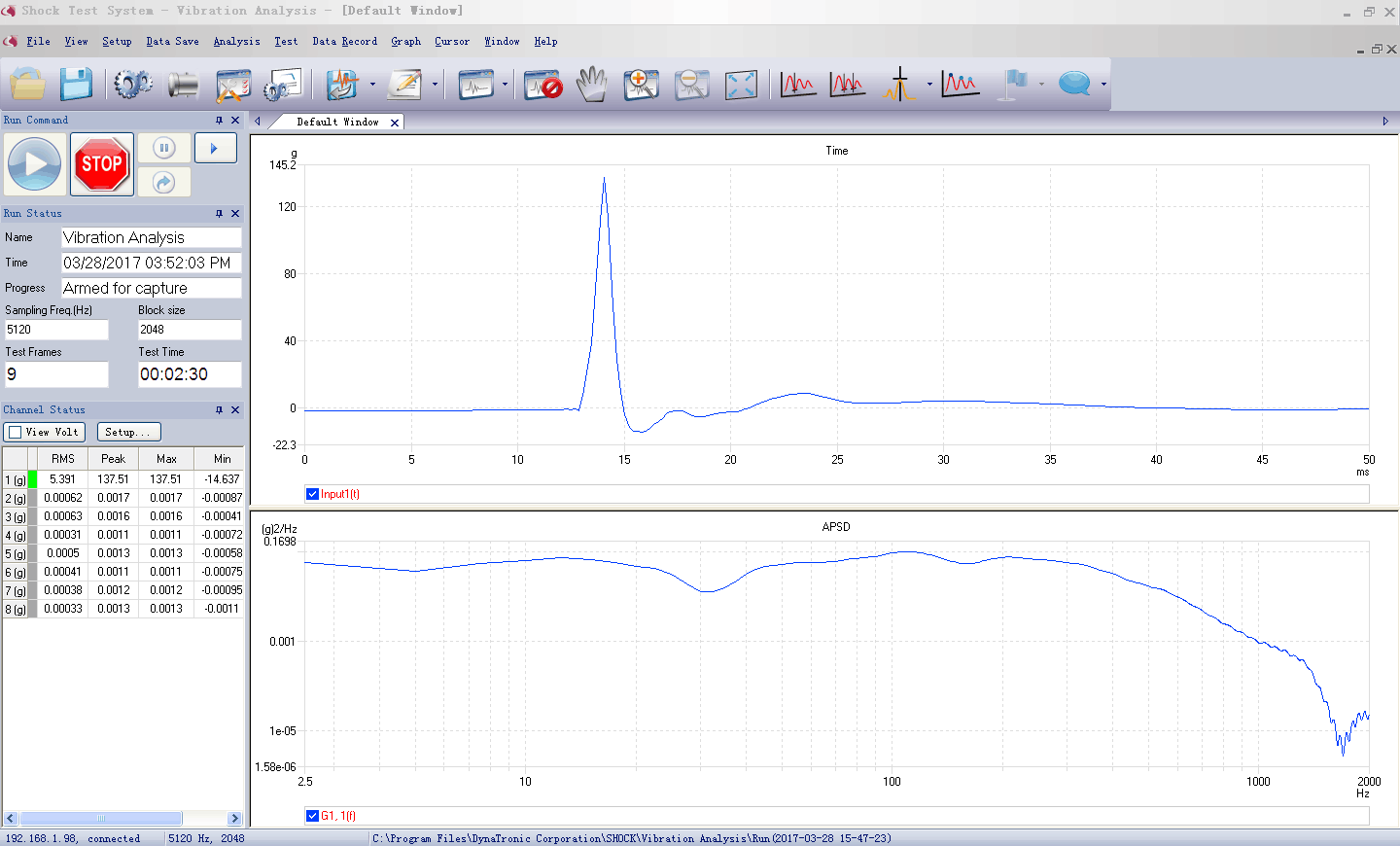

Can collect continuous vibration signals to meet general vibration test requirements.

Sampling Parameters

Sampling Frequency: 80 Hz to 51.2 kHz

Frequency Range: 25 Hz to 20.48 kHz

Sampling Numbers: 128 ~ 65,536 points

Frame Time: Automatic calculation

Automatic calculation

Trigger Channel: Any active channel, specified channel or none

Run Mode: Auto trigger, Manual Trigger

Level: Specified voltage level

Slope: Rising, Falling, Bi-Slope

Delay: Advance or lag trigger, -100%~0%~100%

Damping Ratio: 0.1%~100%

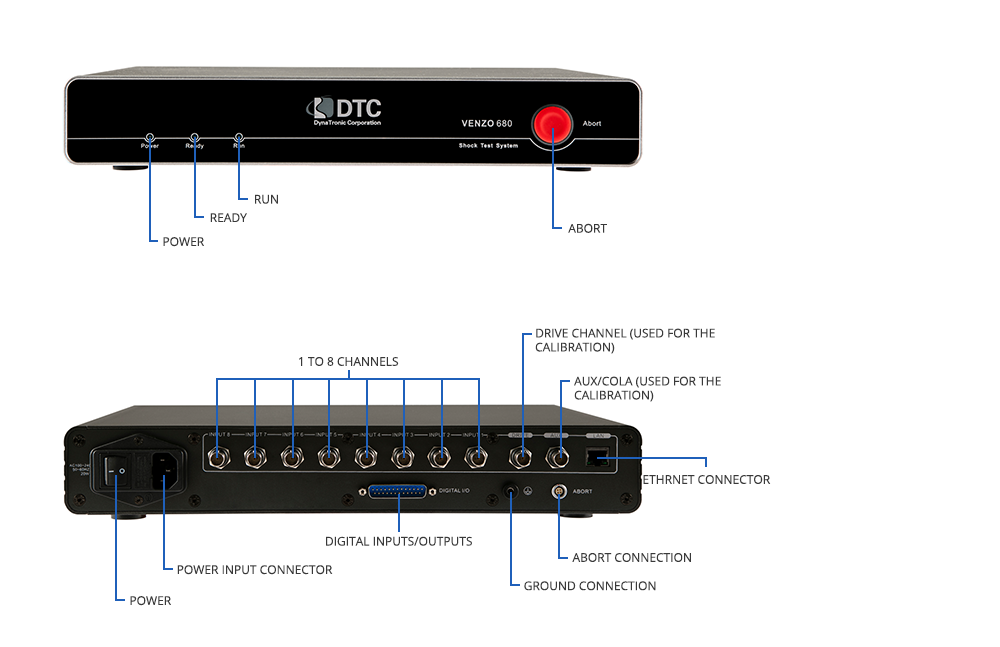

4 Input channels

Up to 204.8kHz sampling rate

24-bit Inputs

1 years Hardware Warranty

<-100 dB THD

DSP Processor

Demo Unit with ALL software

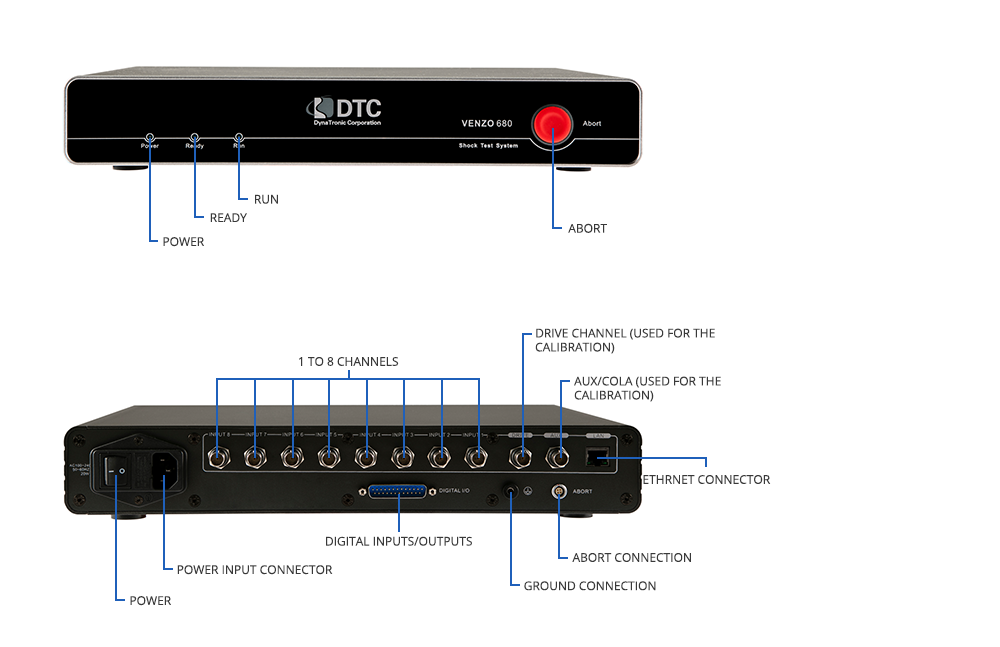

8 Input channels

Up to 204.8kHz sampling rate

24-bit Inputs

1 years Hardware Warranty

<-100 dB THD

DSP Processor

Demo Unit with ALL software

DTC has successfully attended the Automotive Testing Expo China 2023 2023-08-20

Vibro-Shock Test 2022-09-21

How to connect multi-vibration controller? 1970-01-01

By continuing to use the site you agree to our privacy policy.